Driving Sustainability Through Additive Manufacturing

The Evolution of Additive Manufacturing

Additive manufacturing, also known as 3D printing, has emerged as a powerful tool for reducing the environmental impact of production processes. In Saudi Arabia and the UAE, where sustainability is a growing concern, the adoption of additive manufacturing technologies is reshaping industries and fostering a more environmentally conscious approach to manufacturing.

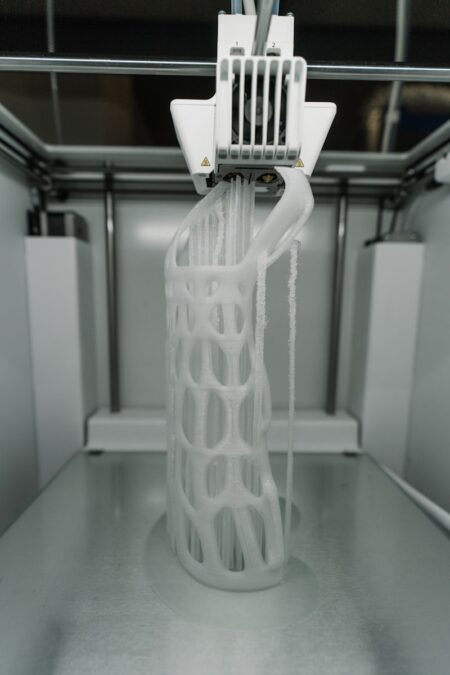

Additive manufacturing represents a departure from traditional subtractive manufacturing methods, where materials are cut away from a solid block to create a final product. Instead, additive manufacturing builds objects layer by layer, using digital designs and materials such as plastics, metals, and ceramics. This process not only reduces material waste but also enables more efficient use of resources, leading to a significant decrease in the environmental footprint of manufacturing operations.

As technology continues to advance, the applications of additive manufacturing are expanding across various industries, from aerospace and automotive to healthcare and consumer goods. In Riyadh and Dubai, where innovation drives success, businesses are harnessing the power of additive manufacturing to create more sustainable products and processes. By embracing this transformative technology, organizations can reduce waste, minimize energy consumption, and contribute to a greener, more sustainable future.

Benefits of Additive Manufacturing for Sustainability

The benefits of additive manufacturing for sustainability are manifold. One of the key advantages is the ability to produce complex geometries and customized designs with minimal material waste. Unlike traditional manufacturing methods, which often result in excess material being discarded, additive manufacturing allows for precise control over the amount of material used, leading to significant reductions in waste and resource consumption.

Moreover, additive manufacturing enables on-demand production, eliminating the need for large-scale manufacturing facilities and extensive inventory storage. This not only reduces the environmental impact of transportation and warehousing but also allows businesses to respond more quickly to changing market demands and consumer preferences. In a fast-paced business environment, agility and flexibility are essential for maintaining competitiveness and driving innovation.

Additionally, additive manufacturing supports the use of sustainable materials, such as biodegradable polymers and recycled metals, further reducing the environmental impact of production. By leveraging these eco-friendly materials and processes, businesses can meet the growing demand for sustainable products and demonstrate their commitment to environmental stewardship. This not only enhances brand reputation but also creates new opportunities for market differentiation and growth.

Embracing Additive Manufacturing for Sustainable Business Practices

For businesses in Saudi Arabia and the UAE, embracing additive manufacturing is essential for driving sustainability and maintaining competitiveness in a rapidly changing world. By integrating additive manufacturing technologies into their production processes, organizations can reduce waste, lower costs, and enhance their environmental performance. However, successful adoption requires strategic planning, investment, and collaboration.

Executive coaching and training programs play a crucial role in preparing business leaders and managers for the adoption of additive manufacturing. By equipping them with the necessary knowledge and skills, organizations can ensure a smooth transition and maximize the benefits of this transformative technology. Additionally, partnerships with technology providers and research institutions can provide access to expertise and resources needed to implement additive manufacturing effectively.

Furthermore, fostering a culture of innovation and sustainability is essential for realizing the full potential of additive manufacturing. Businesses in Riyadh and Dubai must encourage employees to explore new ideas and technologies, fostering an environment where creativity and collaboration thrive. By embracing a forward-thinking mindset and investing in sustainable business practices, organizations can position themselves for long-term success and leadership in their respective industries.

Conclusion: Advancing Sustainability with Additive Manufacturing

In conclusion, additive manufacturing offers a pathway to a more sustainable future for businesses in Saudi Arabia and the UAE. By leveraging the power of this transformative technology, organizations can reduce the environmental impact of production processes, minimize waste, and drive innovation. For business executives, mid-level managers, and entrepreneurs, embracing additive manufacturing is essential for staying ahead of the curve and shaping a more sustainable world.

As both nations continue to prioritize sustainability and innovation, the adoption of additive manufacturing will play a crucial role in driving economic growth and environmental stewardship. By embracing this cutting-edge technology and fostering a culture of sustainability, businesses in Riyadh and Dubai can lead the way in advancing sustainable business practices and creating a better future for generations to come.

#AdditiveManufacturing #EnvironmentalImpactReduction #SustainableProduction #TechnologyAdvancements #BusinessInnovation