Enhancing Tissue Engineering with Computational Modeling

The role of computational modeling in tissue engineering has become increasingly significant as this field advances. Computational modeling and simulation provide powerful tools to optimize tissue engineering processes and product design, enabling researchers to predict and analyze complex biological phenomena with precision. In regions like Saudi Arabia and the UAE, where medical innovation and technological advancement are key priorities, the integration of computational modeling into tissue engineering is paving the way for groundbreaking developments.

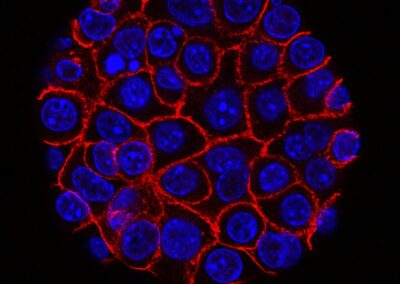

Computational models allow researchers to simulate various biological processes, such as cell growth, tissue development, and biomaterial interactions. These simulations can help identify optimal conditions for tissue engineering, reducing the need for extensive trial and error in laboratory settings. For example, researchers in Riyadh and Dubai are using computational modeling to design scaffolds that support tissue regeneration. By simulating different scaffold structures and materials, they can predict which designs will provide the best environment for cell growth and tissue integration.

Moreover, computational modeling can accelerate the development of tissue-engineered products by providing insights into the underlying mechanisms of tissue formation and regeneration. This understanding enables researchers to develop more effective and efficient strategies for creating functional tissues. In Saudi Arabia and the UAE, where there is a strong emphasis on medical research and innovation, computational modeling is playing a crucial role in advancing tissue engineering and improving healthcare outcomes.

Optimizing Tissue Engineering Processes

One of the key benefits of computational modeling in tissue engineering is its ability to optimize various processes involved in tissue creation. This includes the design of bioreactors, which are devices that provide a controlled environment for tissue growth. Computational models can simulate different bioreactor designs and operating conditions, helping researchers determine the optimal parameters for tissue cultivation. This leads to more efficient and effective tissue engineering processes, saving time and resources.

In addition to bioreactor design, computational modeling can optimize the selection and combination of biomaterials used in tissue engineering. By simulating the interactions between different materials and cells, researchers can identify the best combinations for specific applications. For instance, in Riyadh and Dubai, researchers are using computational models to develop advanced biomaterials that enhance tissue regeneration and integration. These materials can be tailored to mimic the natural extracellular matrix, providing a supportive environment for cell growth and tissue formation.

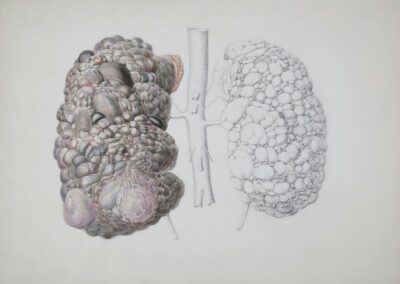

Furthermore, computational modeling can be used to optimize the mechanical properties of tissue-engineered products. This is particularly important for applications where the engineered tissues must withstand mechanical forces, such as in cartilage or bone regeneration. By simulating the mechanical behavior of different tissue constructs, researchers can design products that meet the required strength and durability standards. In the technologically advanced regions of Saudi Arabia and the UAE, these optimizations are contributing to the development of high-quality tissue-engineered products for clinical use.

The Integration of AI, Blockchain, and the Metaverse

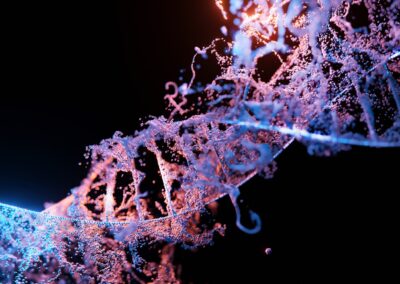

The integration of advanced technologies such as Artificial Intelligence (AI), blockchain, and the metaverse is further enhancing the role of computational modeling in tissue engineering. AI can analyze large datasets and identify patterns that might not be apparent through traditional methods. This capability allows researchers to refine their computational models and improve the accuracy of their simulations. In the innovative environments of Riyadh and Dubai, AI-driven modeling is accelerating the development of advanced tissue-engineered products.

Blockchain technology provides a secure and transparent framework for managing the data generated by computational modeling. By ensuring the traceability and integrity of data, blockchain enhances the reliability of the modeling process and ensures compliance with regulatory standards. This is particularly important in the medical field, where data accuracy and security are paramount. In Saudi Arabia and the UAE, leveraging blockchain technology supports robust and trustworthy tissue engineering practices.

The metaverse offers new opportunities for virtual collaboration and education in tissue engineering. By creating immersive virtual environments, researchers and clinicians can explore and simulate tissue engineering techniques, share knowledge, and collaborate on complex projects. This can accelerate the pace of innovation and improve the quality of tissue-engineered products. In the forward-thinking cities of Riyadh and Dubai, the metaverse is being leveraged to enhance research and development in tissue engineering, fostering a collaborative and innovative medical community.

#TissueEngineering #ComputationalModeling #Simulation #ProductDesign #BusinessSuccess #LeadershipSkills #AI #Blockchain #GenerativeAI #ChangeManagement #ExecutiveCoaching #EffectiveCommunication #ManagementConsulting #SaudiArabia #UAE #Riyadh #Dubai