Transforming the Watchmaking Industry with Robotics

Introduction to Watchmaking Robots

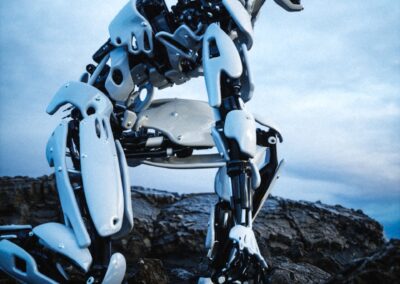

Watchmaking robots have emerged as indispensable tools in the precision manufacturing sector, particularly in regions like Saudi Arabia and the UAE, where technological advancements drive innovation. These robots are engineered to perform high-precision tasks with unparalleled accuracy, revolutionizing the production processes in the watchmaking industry. Equipped with advanced AI algorithms and robotic arms, watchmaking robots streamline manufacturing operations, ensuring consistent quality and craftsmanship in every timepiece produced. By integrating robotics into watchmaking, manufacturers can achieve higher productivity and meet the exacting standards of luxury timepiece enthusiasts worldwide.

In cities such as Riyadh and Dubai, where luxury brands thrive, the adoption of watchmaking robots is transforming the landscape of the watchmaking industry. These robots can execute intricate tasks such as assembly, polishing, and quality control with exceptional precision and efficiency. As a result, watchmakers can optimize their production workflows, reduce lead times, and deliver exquisite timepieces that meet the highest standards of excellence. The use of watchmaking robots reflects a commitment to innovation and craftsmanship, positioning manufacturers for success in the competitive global market for luxury watches.

The Integration of AI and Robotics in Watchmaking

At the core of watchmaking robots lies artificial intelligence (AI), which enables these systems to analyze data and adapt to the intricacies of watch assembly and finishing. AI algorithms optimize manufacturing processes, minimize errors, and enhance overall productivity in watchmaking. This level of automation not only increases efficiency but also ensures that each timepiece meets the precise specifications set by master watchmakers. In Saudi Arabia and the UAE, where luxury watchmaking is an art form, the integration of AI and robotics is driving innovation and setting new standards for craftsmanship.

Furthermore, the use of blockchain technology in watchmaking offers additional benefits in terms of authenticity and provenance. Blockchain can be used to create digital certificates of authenticity for each timepiece, recording its entire production history from assembly to sale. This transparency provides consumers with confidence in the authenticity and value of their luxury watches, strengthening brand reputation and loyalty. By leveraging AI, robotics, and blockchain, watchmakers in Saudi Arabia and the UAE can uphold the heritage of their craft while embracing the opportunities offered by digital transformation.

Executive Coaching and Effective Communication in Implementing Watchmaking Robots

The successful integration of watchmaking robots into manufacturing operations requires effective change management and executive coaching services. Business leaders, production managers, and watch technicians must be equipped with the necessary skills and knowledge to leverage this technology effectively. Executive coaching programs can provide guidance on strategic planning, process optimization, and workforce training, ensuring that organizations maximize the benefits of watchmaking robots. By empowering leaders with the tools and resources they need, watchmakers can navigate the complexities of digital transformation and preserve the artistry of watchmaking.

Effective communication is also essential in ensuring the smooth adoption of watchmaking robots in the workshop. Watchmakers and technicians must understand the advantages of using robots for precision tasks and be reassured about the technology’s reliability and accuracy. Clear communication channels should be established to address any concerns and foster collaboration between human workers and robotic systems. By involving employees in the implementation process and soliciting their feedback, watchmakers can build trust and ensure a successful transition to robotic-assisted manufacturing.

Moreover, management consulting services can offer valuable insights and support in optimizing the use of watchmaking robots within manufacturing facilities. Consultants can assist with technology assessment, process redesign, and performance monitoring, helping businesses achieve their productivity and efficiency goals. By leveraging executive coaching, effective communication, and management consulting, watchmakers in Saudi Arabia and the UAE can position themselves for long-term success in the luxury watch market.

The Impact of Watchmaking Robots on Craftsmanship and Innovation

The integration of watchmaking robots into manufacturing processes has a profound impact on craftsmanship, innovation, and brand reputation. These advanced systems enable watchmakers to achieve unprecedented levels of precision and consistency in their timepiece production. By automating repetitive tasks and minimizing human error, watchmaking robots free up skilled artisans to focus on creative design and innovation. In regions like Riyadh and Dubai, where luxury watchmaking is synonymous with excellence, watchmaking robots are driving advancements in craftsmanship and setting new standards for quality and innovation.

Furthermore, the data generated by watchmaking robots provides valuable insights for process optimization and continuous improvement initiatives. By analyzing production metrics and performance data, watchmakers can identify areas for enhancement and implement targeted interventions to drive operational excellence. This data-driven approach ensures that every timepiece meets the exacting standards of quality and craftsmanship expected by luxury watch enthusiasts worldwide. In the dynamic and competitive landscape of luxury watchmaking, the integration of watchmaking robots is essential for maintaining a competitive edge and driving innovation in the industry.

Conclusion

In conclusion, watchmaking robots are revolutionizing the precision manufacturing sector, offering unparalleled accuracy and efficiency in the production of luxury timepieces. With the support of executive coaching, effective communication, and management consulting, watchmakers can successfully integrate robotic technology into their operations and achieve superior performance. As the adoption of watchmaking robots continues to grow, the future of luxury watchmaking in Saudi Arabia and the UAE looks brighter than ever, with enhanced craftsmanship, innovation, and brand reputation driving success in the global market.

The journey towards integrating watchmaking robots into manufacturing processes is not without challenges. Watchmakers must invest in training their workforce to operate and maintain these advanced systems effectively. Additionally, ongoing research and development are necessary to ensure that watchmaking robots continue to evolve and adapt to changing industry demands. Despite these challenges, the benefits of watchmaking robots in terms of precision, efficiency, and innovation far outweigh the initial investment, positioning watchmakers for sustained success in the luxury watch market.

The future of watchmaking lies at the intersection of tradition and technology, where skilled artisans collaborate with robotic systems to create timepieces of unparalleled beauty and precision. By embracing the opportunities offered by watchmaking robots, watchmakers in Saudi Arabia and the UAE can uphold the heritage of their craft while embracing the possibilities of the digital age. With a commitment to excellence and innovation, these watchmakers are poised to shape the future of luxury watchmaking and continue to captivate enthusiasts around the world.

—

#WatchmakingRobots #PrecisionManufacturing #AIinManufacturing #BlockchaininManufacturing #Craftsmanship #ExecutiveCoaching #ChangeManagement #SaudiArabia #UAE #Dubai #Riyadh