Exploring the Boundless Potential of 3D Printing in Modern Business

The Role of Metals in 3D Printing: Enhancing Manufacturing Efficiency

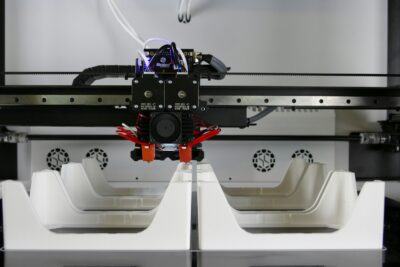

In the realm of 3D Printing Materials, metals have emerged as a game-changer, significantly enhancing manufacturing efficiency and product quality. The use of metals such as titanium, aluminum, and stainless steel in 3D printing allows for the creation of parts that are not only strong but also lightweight and complex in design. This versatility of 3D printing materials is particularly beneficial for industries in Saudi Arabia and the UAE, where there is a high demand for customized and durable components in sectors such as aerospace, automotive, and construction.

Metals in 3D printing offer numerous advantages, including reduced waste and faster production times. Traditional manufacturing methods often involve subtractive processes that cut away excess material, leading to significant waste. In contrast, additive manufacturing, or 3D printing, builds objects layer by layer, minimizing material waste and allowing for more precise control over the final product. This efficiency is crucial for businesses looking to optimize their operations and reduce costs, particularly in competitive markets like Riyadh and Dubai.

Furthermore, the ability to produce complex geometries that would be impossible or impractical with traditional methods opens new avenues for innovation. For instance, in the aerospace industry, 3D printed metal parts can be designed with internal structures that reduce weight while maintaining strength, leading to more fuel-efficient aircraft. Similarly, in the medical field, customized implants and prosthetics can be produced to exact specifications, improving patient outcomes. The strategic use of 3D printing with metals underscores the importance of embracing advanced manufacturing technologies to stay ahead in the global market.

Plastics and Ceramics in 3D Printing: Versatility for Diverse Applications

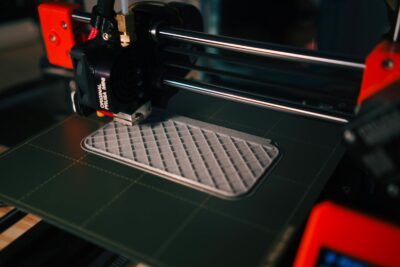

While metals offer strength and durability, plastics and ceramics provide a different kind of versatility in 3D printing. Plastics, such as ABS, PLA, and nylon, are widely used due to their ease of use, affordability, and range of properties that can be tailored for specific applications. For businesses in Saudi Arabia and the UAE, leveraging plastic 3D printing can lead to significant cost savings and increased flexibility in product development.

Plastic 3D printing is particularly advantageous for producing prototypes, consumer products, and lightweight parts. The ability to quickly produce and test prototypes accelerates the product development cycle, allowing companies to bring new products to market faster. This rapid iteration process is essential for entrepreneurs and mid-level managers looking to innovate and respond to market demands swiftly. Additionally, the use of plastics in 3D printing supports sustainable practices, as many plastics can be recycled and reused, aligning with global trends towards environmental responsibility.

Ceramics, on the other hand, bring a unique set of properties to 3D printing, including high heat resistance, biocompatibility, and aesthetic appeal. These characteristics make ceramics ideal for applications in the medical, dental, and art sectors. For example, 3D printed ceramic implants can be customized to fit a patient’s anatomy perfectly, improving the success rates of surgical procedures. In the art world, ceramics allow for the creation of intricate designs and sculptures that would be difficult to achieve through traditional methods. The versatility of ceramics in 3D printing opens up new possibilities for creative and functional applications, highlighting the importance of this material in the future of manufacturing.

Leveraging 3D Printing for Business Success in the Gulf Region

The adoption of 3D printing technologies in the Gulf region, particularly in cities like Riyadh and Dubai, is driving significant business transformation. Executive coaching services and management consulting firms are playing a crucial role in helping businesses navigate this technological shift. By understanding the versatility of 3D printing materials and their applications, executives can make informed decisions that enhance their company’s competitive edge.

Effective communication about the benefits and potential of 3D printing is essential for successful implementation. Business leaders need to articulate the value proposition of 3D printing to stakeholders, including employees, investors, and customers. This involves highlighting the cost savings, efficiency gains, and innovative possibilities that 3D printing offers. Management consulting firms can assist in developing strategies that integrate 3D printing into existing workflows, ensuring a smooth transition and maximizing the technology’s impact.

Moreover, the integration of 3D printing with emerging technologies such as Artificial Intelligence (AI) and Blockchain can further enhance business operations. AI can optimize the design and manufacturing processes, while Blockchain can ensure secure and transparent supply chains. In the context of the Metaverse, 3D printing can enable the creation of virtual objects that can be replicated in the physical world, offering new business opportunities. By embracing these technologies, businesses in Saudi Arabia and the UAE can lead in innovation and set new standards in their industries.

The Future of 3D Printing: Generative AI and Beyond

Generative Artificial Intelligence (AI) is poised to revolutionize 3D printing, taking the versatility of materials to new heights. Generative AI algorithms can design complex structures that optimize material usage, strength, and functionality. This advancement is particularly relevant for industries in the Gulf region that require high-performance materials, such as aerospace, healthcare, and manufacturing.

The integration of Generative AI with 3D printing enables the creation of highly customized products that meet specific needs and preferences. For instance, in the healthcare sector, AI-driven design can produce patient-specific implants and devices, enhancing treatment outcomes. In the manufacturing industry, generative AI can optimize the design of components to reduce weight and material costs while maintaining structural integrity. This synergy between AI and 3D printing is driving a new era of innovation, where the possibilities are limited only by imagination.

Businesses in Saudi Arabia and the UAE are well-positioned to capitalize on these advancements, given their strong commitment to technological innovation and economic diversification. By investing in generative AI and 3D printing technologies, companies can create a competitive advantage and drive sustainable growth. Executive coaching and management consulting services can provide the necessary guidance and expertise to harness these technologies effectively, ensuring that businesses remain at the forefront of industry trends.

Conclusion: Embracing 3D Printing for Strategic Advantage

In conclusion, the versatility of 3D printing materials such as metals, plastics, and ceramics is transforming the manufacturing landscape. For businesses in Saudi Arabia, the UAE, Riyadh, and Dubai, leveraging these materials can lead to significant advancements in efficiency, innovation, and product quality. Executive coaching services and management consulting firms play a vital role in guiding businesses through this technological transition, helping them to communicate effectively, integrate new processes, and capitalize on emerging opportunities.

As generative AI and other advanced technologies continue to evolve, the potential for 3D printing will only grow. Businesses that embrace these innovations will be better equipped to navigate the complexities of the modern market, drive growth, and achieve long-term success. By understanding and utilizing the full range of 3D printing materials and their applications, companies can unlock new possibilities and set new standards in their industries.

—

#3DPrinting, #BusinessInnovation, #SaudiArabia, #UAE, #Riyadh, #Dubai, #Manufacturing, #AI, #GenerativeAI, #Blockchain, #Metaverse