The Role of Predictive Maintenance with IoT in Enhancing Equipment Efficiency

Optimizing Equipment Performance through Predictive Maintenance

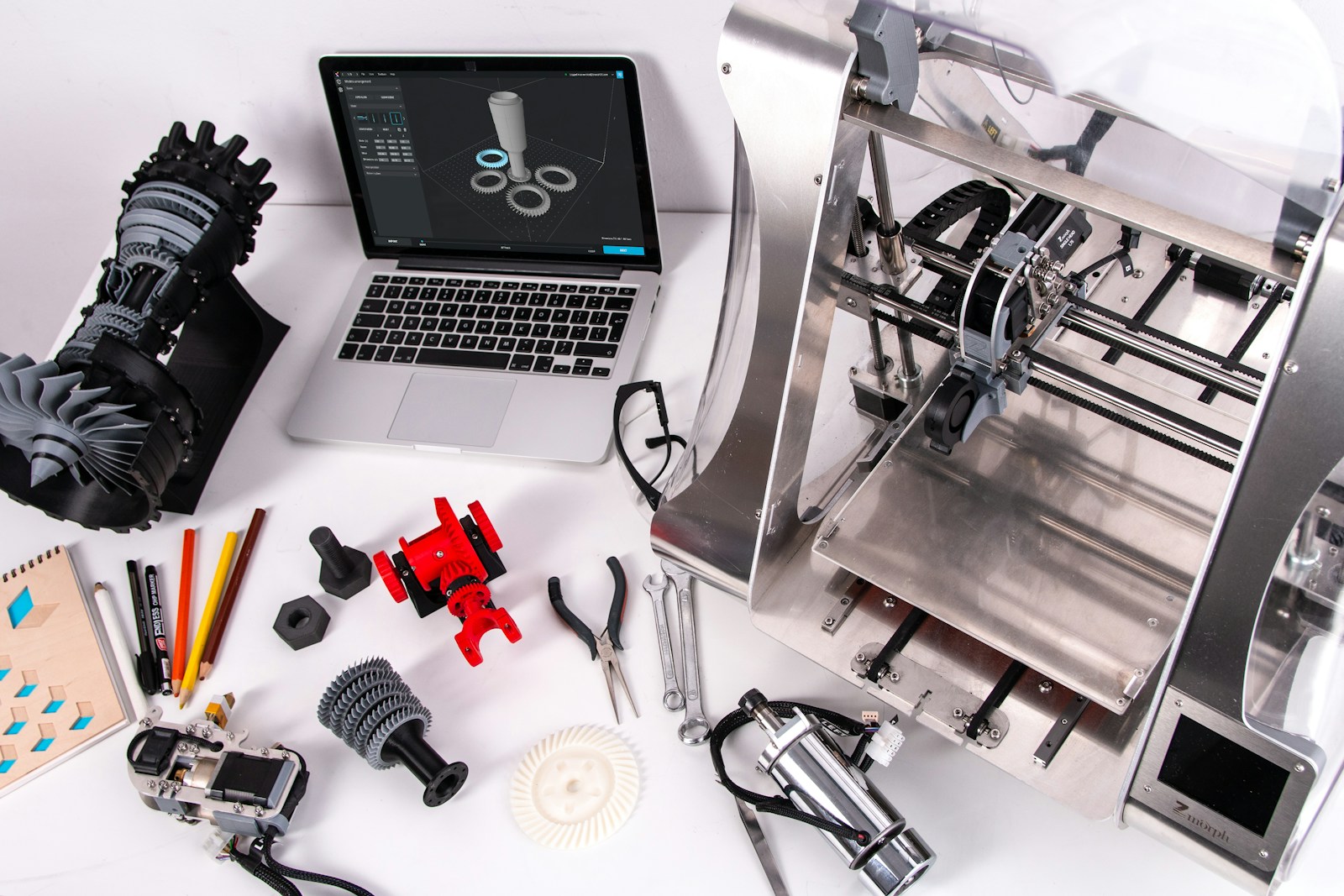

Predictive maintenance with IoT is revolutionizing the management of industrial equipment by significantly reducing downtime and boosting operational efficiency. This advanced approach leverages Internet of Things (IoT) technology to continuously monitor the health and performance of machinery through real-time data collection. By analyzing this data, predictive maintenance systems can forecast potential failures before they occur, allowing for timely interventions that prevent costly breakdowns.

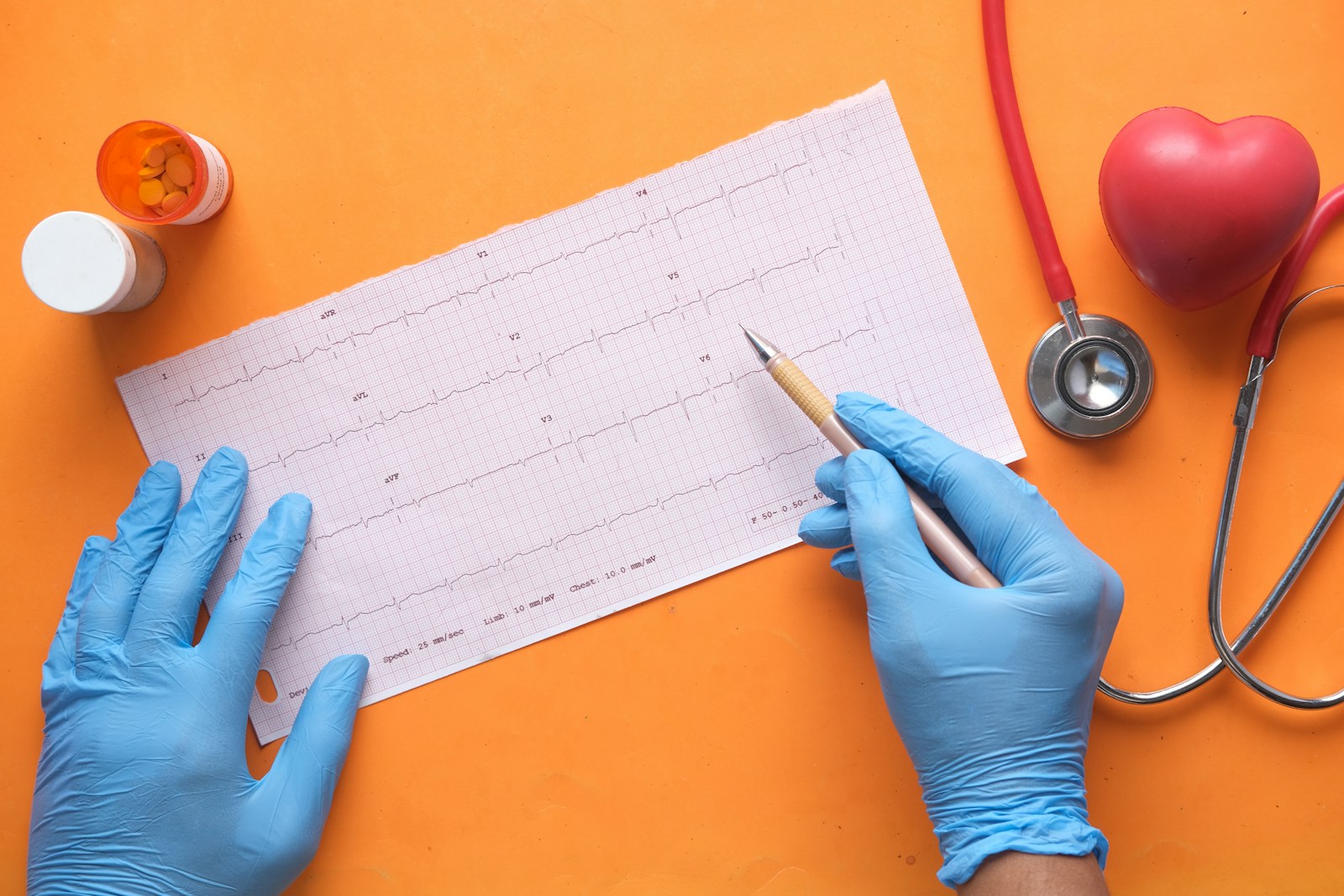

In regions like Saudi Arabia and the UAE, where industrial sectors are rapidly advancing, predictive maintenance is becoming a crucial component of operational strategy. For instance, in Riyadh’s growing industrial hubs, businesses are deploying IoT sensors to track equipment performance metrics such as temperature, vibration, and pressure. This proactive approach enables maintenance teams to address issues early, thereby extending the lifespan of equipment and ensuring smooth production processes.

Similarly, in Dubai’s bustling industrial and commercial landscape, predictive maintenance solutions are being used to enhance the efficiency of equipment across various sectors. The ability to predict and prevent equipment failures not only minimizes operational disruptions but also contributes to substantial cost savings. As organizations in these regions continue to invest in modern technologies, predictive maintenance with IoT stands out as a key driver of operational excellence and competitive advantage.

Reducing Downtime with Advanced Predictive Maintenance Techniques

The implementation of predictive maintenance with IoT offers a transformative approach to managing industrial equipment by focusing on prevention rather than reaction. Traditional maintenance methods often involve scheduled checks or responding to equipment failures after they occur. In contrast, predictive maintenance uses data analytics and machine learning algorithms to predict when maintenance should be performed based on the actual condition of the equipment.

In Saudi Arabia’s thriving industrial sector, this shift towards predictive maintenance is helping companies reduce unplanned downtime and avoid costly repairs. For example, IoT-enabled sensors in manufacturing plants continuously monitor machinery conditions, allowing for the identification of potential issues before they escalate. This proactive maintenance strategy not only minimizes production halts but also ensures that equipment operates at peak efficiency.

In the UAE, businesses are similarly benefiting from predictive maintenance technologies. By leveraging real-time data and advanced analytics, organizations can optimize maintenance schedules and allocate resources more effectively. This approach reduces the risk of equipment failures and enhances overall productivity. As industries across Dubai and Abu Dhabi adopt these technologies, predictive maintenance is becoming a cornerstone of operational strategies aimed at maximizing equipment reliability and performance.

Integrating Predictive Maintenance with Modern Technologies

Enhancing Efficiency through IoT and Advanced Analytics

The integration of predictive maintenance with IoT and modern technologies like artificial intelligence (AI) and blockchain is further advancing the efficiency of industrial operations. AI algorithms analyze data collected from IoT sensors to identify patterns and predict potential equipment failures with high accuracy. This combination of technologies allows for more precise maintenance predictions and better decision-making.

In Riyadh, the incorporation of AI with IoT in predictive maintenance systems is driving significant improvements in operational efficiency. For instance, machine learning models are used to analyze historical and real-time data, providing actionable insights that guide maintenance strategies. This data-driven approach helps businesses optimize maintenance schedules, reduce costs, and enhance the performance of their equipment.

Similarly, in Dubai’s high-tech industries, predictive maintenance systems integrated with blockchain technology are ensuring the integrity and security of maintenance data. Blockchain’s decentralized ledger provides a tamper-proof record of equipment conditions and maintenance activities, enhancing transparency and trust in maintenance processes. This integration not only boosts efficiency but also supports compliance with industry standards and regulations.

Strategic Benefits of Implementing Predictive Maintenance

The strategic benefits of predictive maintenance with IoT extend beyond operational improvements to include enhanced business performance and competitive advantage. By adopting predictive maintenance strategies, organizations can achieve significant cost savings, improve equipment reliability, and drive overall business success.

In Saudi Arabia, companies implementing predictive maintenance are experiencing reduced operational disruptions and increased equipment uptime. This proactive approach to maintenance helps businesses avoid expensive emergency repairs and extend the lifecycle of their machinery. The improved efficiency and reliability of equipment contribute to a more stable and productive operation, positioning companies for long-term success.

In the UAE, the strategic adoption of predictive maintenance technologies is driving innovation and growth across various industries. Businesses are leveraging these technologies to gain a competitive edge, enhance customer satisfaction, and achieve operational excellence. As predictive maintenance becomes increasingly integral to industrial strategies, organizations in Dubai and beyond are setting new standards for efficiency and performance in the modern business landscape.

Conclusion: The Future of Industrial Efficiency with Predictive Maintenance

In conclusion, predictive maintenance with IoT is reshaping the landscape of industrial operations by offering a proactive approach to equipment management. By leveraging real-time data, advanced analytics, and modern technologies, businesses can reduce downtime, enhance efficiency, and achieve substantial cost savings. For companies in Saudi Arabia, the UAE, and other dynamic markets, predictive maintenance is not only a strategic advantage but also a critical component of operational excellence. Embracing these technologies positions organizations for sustained success and growth in an increasingly competitive global marketplace.

—

#PredictiveMaintenance, #IoT, #IndustrialEquipment, #DowntimeReduction, #Efficiency, #ArtificialIntelligence, #Blockchain, #GenerativeAI, #ModernTechnology, #BusinessSuccess, #LeadershipSkills, #ExecutiveCoaching, #Riyadh, #Dubai, #UAE, #SaudiArabia