Transforming Manufacturing with Functional End-Use Parts

The Evolution of 3D Printing in Manufacturing

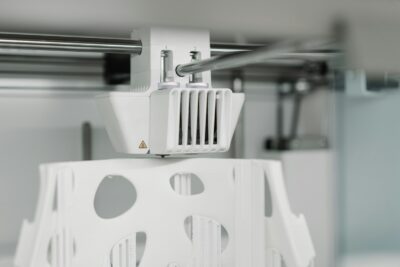

Functional End-Use Parts in 3D Printing are revolutionizing the landscape of manufacturing, offering unparalleled flexibility and efficiency in producing customized components. This transformative technology has gained significant traction in regions like Saudi Arabia and the UAE, where industries are increasingly embracing innovation to gain a competitive edge. From Riyadh to Dubai, businesses are leveraging 3D printing to streamline production processes and meet the growing demand for personalized products.

The ability to create functional end-use parts directly from digital designs has opened up new possibilities for manufacturers across various sectors. Whether in automotive, aerospace, healthcare, or consumer goods, 3D printing enables companies to produce complex geometries and intricate details that were once challenging or impossible to achieve with traditional manufacturing methods. This flexibility empowers businesses to iterate rapidly, optimize designs, and respond swiftly to changing market demands.

In addition to enhancing operational efficiency, the adoption of 3D printing for functional end-use parts aligns with broader sustainability initiatives. By reducing material waste and energy consumption, this technology supports environmentally conscious manufacturing practices. Furthermore, the localized production enabled by 3D printing reduces reliance on global supply chains, enhancing resilience and mitigating risks associated with disruptions.

Driving Business Success Through Innovation

The integration of 3D printing into manufacturing processes requires a strategic approach to change management and organizational development. Executive coaching services play a crucial role in guiding leadership teams through this transition, helping them navigate the complexities of implementing new technologies and workflows. Effective communication is essential to ensure alignment across all levels of the organization and foster a culture of innovation and continuous improvement.

For businesses in Saudi Arabia and the UAE, where economic diversification and technological advancement are key priorities, embracing 3D printing offers a pathway to sustainable growth and competitive advantage. Management consulting firms specializing in emerging technologies can provide valuable insights and support in developing tailored strategies for integrating 3D printing into existing operations. By leveraging expertise in areas such as Artificial Intelligence and Blockchain, businesses can unlock new opportunities for efficiency and innovation.

Leadership and management skills are critical for driving successful implementation and maximizing the benefits of 3D printing for functional end-use parts. Strong leadership ensures that the vision for adopting this technology is clearly communicated and understood throughout the organization. Project management expertise is essential for overseeing implementation plans, managing resources effectively, and mitigating potential risks. By fostering a culture of collaboration and learning, companies can empower employees to embrace change and drive innovation.

The Future of Manufacturing: A Conclusion

As the production of functional end-use parts becomes increasingly common with 3D printing, the manufacturing industry stands on the brink of a profound transformation. From Saudi Arabia to the UAE, businesses are embracing this technology to enhance efficiency, reduce costs, and unlock new opportunities for innovation. By leveraging the power of 3D printing and investing in leadership development and organizational change, companies can position themselves for long-term success in a rapidly evolving global market.

Embracing 3D Printing for Business Growth

In conclusion, the adoption of 3D printing for functional end-use parts represents a paradigm shift in manufacturing. By harnessing the potential of this technology, businesses can achieve greater agility, sustainability, and competitiveness. With the right strategic approach and investment in talent and resources, companies in Saudi Arabia, the UAE, and beyond can unlock the full benefits of 3D printing and drive business growth in the digital age.

Continued Innovation in Manufacturing

Looking ahead, the evolution of 3D printing technology is poised to accelerate, ushering in a new era of manufacturing innovation. As advancements in materials science, robotics, and artificial intelligence continue to expand the capabilities of 3D printing, businesses must remain agile and adaptable to stay ahead of the curve. By embracing a culture of innovation and investing in research and development, companies can continue to push the boundaries of what is possible with 3D printing and shape the future of manufacturing.

—

#FunctionalEndUseParts #3DPrinting #SaudiArabia #UAE #Riyadh #Dubai #ChangeManagement #ExecutiveCoaching #EffectiveCommunication #BusinessSuccess #ManagementConsulting #ArtificialIntelligence #Blockchain #TheMetaverse #GenerativeAI #Leadership #ProjectManagement